Some of the common applications for Teflon coating include:

Aerospace

Teflon coating is used on aircraft and spacecraft parts to improve their functionality and performance.

Industrial Machinery

Teflon coating is used on industrial machinery, including pumps, gears, and other moving parts, to reduce friction.

Teflon Coated Ammunition and Bullets

Sometimes Teflon coating is added to bullets to improve their ballistic performance. These are only allowed in states where Teflon-coated bullets are legal.

Teflon Coated Steel Tube

Steel tubes of various kinds are common components and good candidates for teflon coatings.

Electronics

Electronic components, such as connectors and switches, often have Teflon coating on them, making them resistant to dust, moisture, and other environmental factors.

Marine

Propellers and hulls with a Teflon coating are much more resistant to corrosion than marine equipment that don’t have Teflon.

Heavy Equipment

Excavators, bulldozers, and cranes can have Teflon coating too, reducing friction and improving their overall performance.

Teflon Coated Foil

Teflon-coated aluminum foil is often used for heat-sealing workstations, laboratory table covers, and more.

Teflon Coated Wire

Bailing wire and other types of metal wires are often coated in teflon to protect the wire from heat, chemicals, friction, and provide additional electrical insulation and durability.

Teflon Coated Fasteners

Bolts and other fasteners are frequently coated in Teflon to improve their durability and functionality.

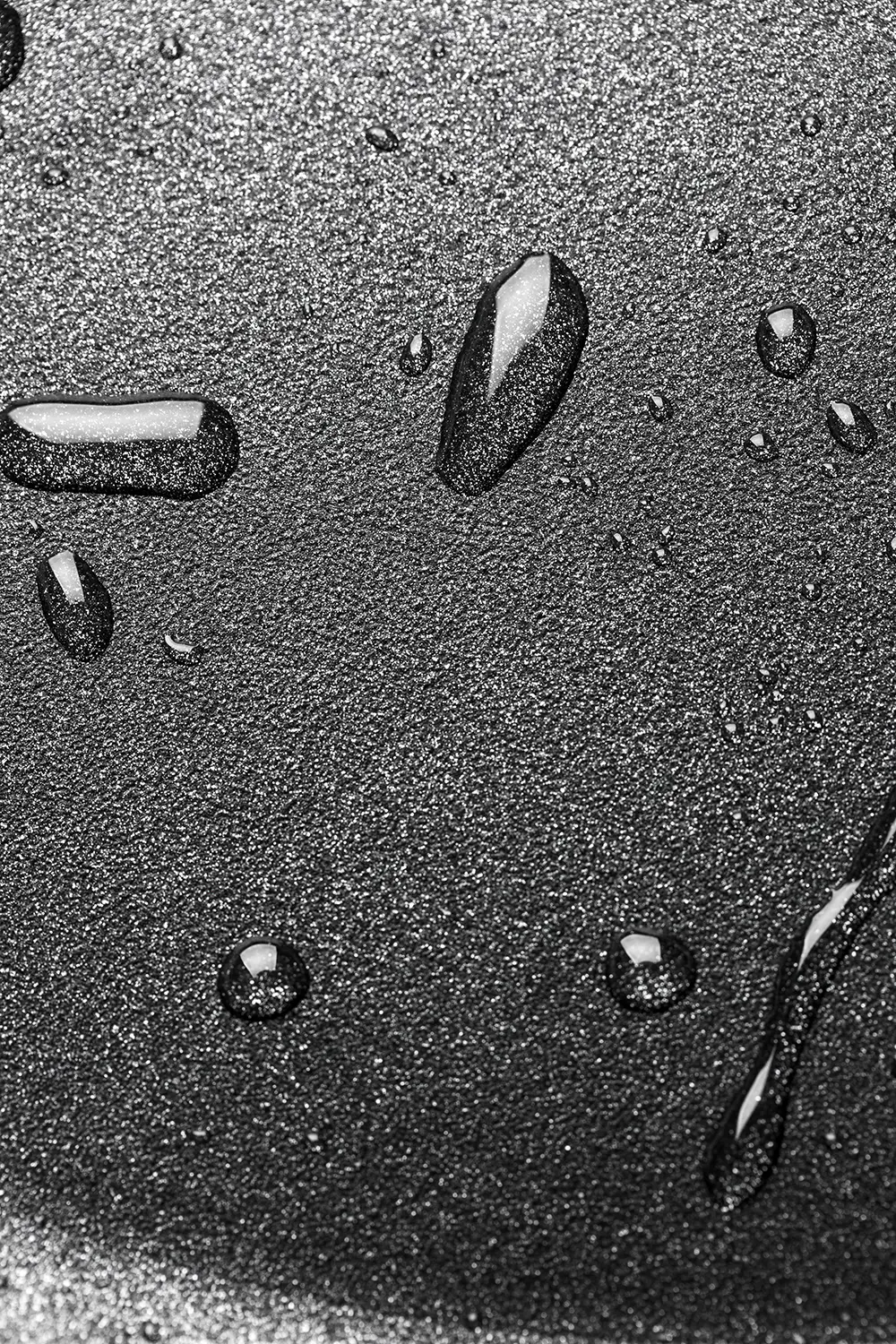

Teflon Coated Metal

Metal sheeting and other components are good candidates for teflon coating. Teflon coated steel and aluminum components are better protected from the elements and perform better in certain environments.

These are just a handful of examples, but the versatility of Teflon coating makes it suitable for a wide range of industries and applications.